Unveiling the Magic: How Does a 3D Printer Work?

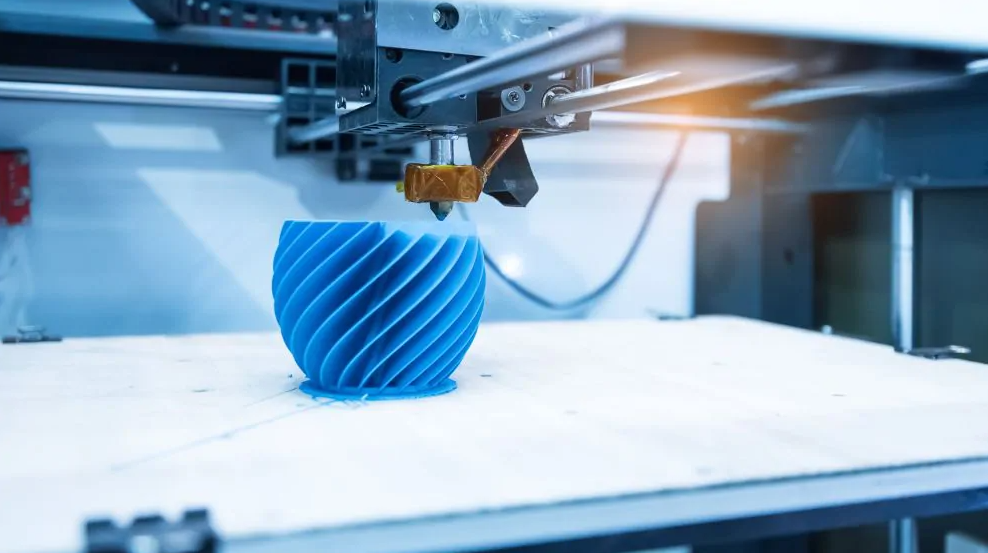

In the realm of modern manufacturing and innovation, 3D printing stands out as a revolutionary technology that has transformed the way we create objects. From intricate prototypes to functional parts and even artistic creations, 3D printers have found applications in diverse fields ranging from aerospace engineering to healthcare and fashion. But how exactly does this seemingly magical process work? Let’s delve into the inner workings of a 3D printer and unveil the secrets behind its operation.

Understanding the Basics: Additive Manufacturing

At the heart of every 3D printer lies the principle of additive manufacturing. Unlike traditional subtractive manufacturing processes, where material is removed from a solid block to create a desired shape, additive manufacturing builds objects layer by layer from the bottom up. This approach allows for unprecedented flexibility and complexity in design, enabling the creation of geometries that were previously unattainable.

The Components:

- 3D Modeling Software: The process begins with the creation of a digital 3D model using specialized software. This model serves as the blueprint for the object to be printed and defines its shape, size, and other characteristics.

- Slicing Software: The 3D model is then sliced into thin horizontal layers, typically ranging from fractions of a millimeter to several millimeters in thickness. Each layer is converted into a set of instructions that the printer can understand, specifying the path that the print head will follow and the deposition of material.

- Printing Material: Various materials can be used in 3D printing, including plastics, metals, ceramics, and even biological materials like living cells. The choice of material depends on the desired properties of the final object, such as strength, flexibility, or biocompatibility.

- Print Bed: The print bed is the platform on which the object is built. It provides a stable surface for the first layer of material to adhere to and ensures dimensional accuracy throughout the printing process.

- Print Head/Nozzle: The print head is responsible for depositing the printing material onto the print bed layer by layer. It moves along the X, Y, and Z axes according to the instructions generated by the slicing software, precisely controlling the deposition of material to form each layer of the object.

- Control System: The control system coordinates the movements of the print head and the operation of other components, ensuring precise synchronization to produce accurate and high-quality prints.

The Printing Process:

- Preparation: Before printing begins, the printer must be calibrated to ensure optimal performance. This involves leveling the print bed, loading the printing material into the extruder, and configuring the printing parameters such as layer height and printing speed.

- Printing: Once everything is set up, the printing process begins. The print head heats the printing material to its melting point and extrudes it onto the print bed in thin layers. As each layer is deposited, the print bed moves down (or the print head moves up) to make room for the next layer.

- Layer-by-Layer Assembly: This layer-by-layer assembly continues until the entire object is completed. Depending on the complexity and size of the object, the printing process can take anywhere from minutes to several hours or even days.

- Post-Processing: Once the printing is finished, the object may require post-processing to remove any support structures, smooth rough surfaces, or apply finishing touches such as painting or polishing.

Conclusion:

In conclusion, the operation of a 3D printer is a fascinating blend of digital design, precision engineering, and material science. By harnessing the power of additive manufacturing, 3D printers have unlocked a world of possibilities for innovation and creativity, allowing us to bring our ideas to life with unprecedented speed and efficiency. As the technology continues to evolve and improve, we can only imagine the exciting new frontiers that await us in the realm of 3D printing.